Solid Floors

Underfloor heating designed and installed by experts with over 5 million metres of UFH pipe installed nationwide

For Screed or Concrete

These systems are designed with the UFH pipes encapsulated in screed or concrete. The depth can range from 20mm encased in the screed to 200mm and beyond in concrete. Our typical install depths are 50mm for liquid screeds or 75mm for concrete screeds for home use. These can be coloured and polished or used for other floor finishes to be installed over the surface later.

Underfloor heating with liquid screed floor

Liquid Screeds are designed to provide a smooth, level surface before the application of the final floor finishes.

Liquid floor screeds have many advantages:

- Installation of liquid floor screed is less labour intensive and faster than the laying of sand cement screed.

- Screed depths can be reduced significantly, meaning you can increase the thermal efficiency of your property by installing thicker floor insulation. This can be as thin as 20mm when overlaying on a solid sub-base.

- A reduced depth of floor screed means reduced weight and reduced drying times. Typically, 1 day per mm of depth up to 40mm and 2 days per mm thereafter. Fast drying alternatives are available as are cement based liquid screeds.

- Liquid Screed can be walked on 24 – 48 hours after installation, providing minimal downtime for other trades on site.

- Liquid Screed can be force dried – as early as 7 days after application. This can be done using the underfloor heating system assuming it has been commissioned.

Structural Concrete Floors

Underfloor heating systems can be incorporated within load-bearing structural floors, in a variety of applications, from factories or warehouses to schools and leisure complexes and domestic dwellings.

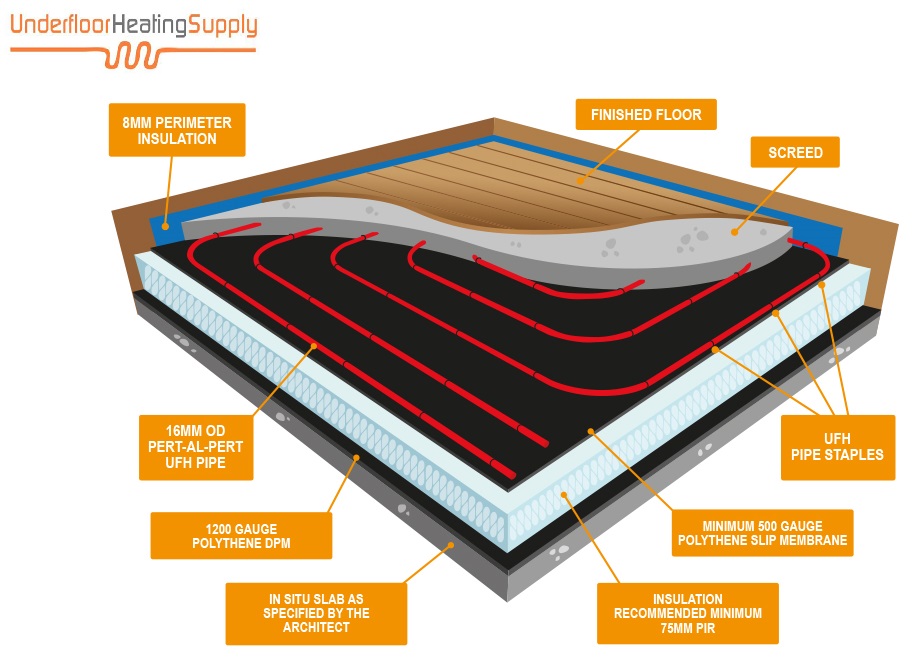

The construction of a structural slab will start with an engineer’s design. This will dictate the concrete slab depth and reinforcement type. The floor construction generally comprises compacted hardcore, suitable insulation boards of the required density and thickness covered with DPC barrier, spacers, and reinforcement, underfloor heating pipes attached with a second layer of reinforcement ready for concrete encasement.

The concrete floor can be power floated to a hard smooth finish or polished to a smooth, shiny and light reflective finish. Other finishes can be applied to the surface such as tiles, engineered wood, laminate, stone paving or marble.

Polished concrete floor with underfloor heating

Polished concrete floors are low maintenance, as they are more durable and easier to clean than many flooring options. Its relatively high coefficient of friction can make it non-slippery. Polished concrete reduces dust mites and allergen problems and does not support mould growth. Anecdotal evidence suggests highly reflective polished concrete reduces lighting needs and improves natural lighting.

Polished concrete flooring is hard wearing and will not naturally chip or dent like softer surfaces such as timber. Cleaning with warm water and flooring conditioner once a week is the only maintenance required. A concrete floor that has been hardened and polished will have an extremely long-life expectancy compared to other flooring. For example, carpets that may only last a couple of years, but a polished concrete floor that has been properly maintained may give 100+ years of service.

Managing thermal risk

After the heating and concrete installation is complete and the concrete has been fully cured (min 28 days), we advise our customers to start the water temperature at 25 degrees and turn the water temperature up by two degrees Celsius each day to prevent shock to the concrete. This should not exceed 45 degrees Celsius (water temperature). Once reached we recommend the water temperature be lowered two degrees Celsius each day back down to 25 Celsius. Once this cycle is complete the system water temperature can be raised 2 degrees per day until the operating temperature is reached. Following this procedure will massively reduce the risk of thermal shock.

It is imperative that the underfloor heating is not switched on while the concrete is curing. This will cause it to dry out too quickly and produce an inferior-quality of the concrete slab. Our expert concrete installers provide this sort of valuable advice both before and after installation.

At Underfloor Heating Installers we provide expert guidance on all aspects of polished concrete with underfloor heating and provide full guidance to our customers before, during and after installation. Our in-house teams lay concrete as a specialist job.

Get Exclusive Updates

Sign up for our newsletter to receive exclusive news, offers and promotions:

We take your privacy seriously, please see our privacy policy for more information.

Our Happy Customers

Thank you to our customers for reaching out and providing us with valuable feedback.