Suspended Floors

Underfloor heating designed and installed by experts with over 5 million metres of UFH pipe installed nationwide

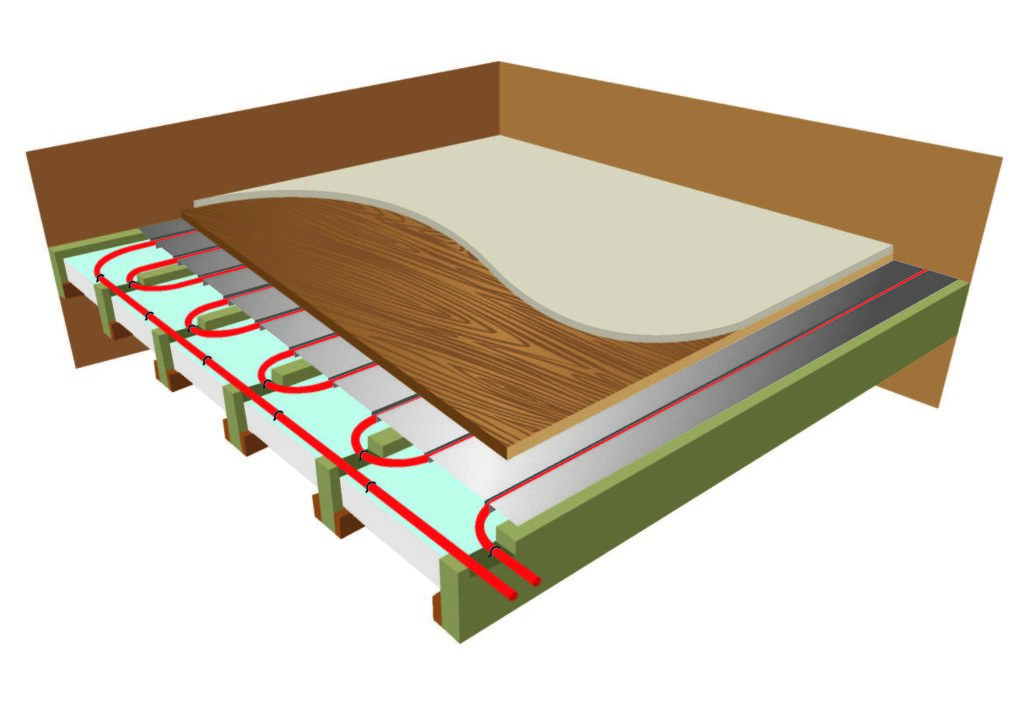

For Timber Suspended Floors

Timber-suspended floors are constructed using floorboards laid on floor joists. The joists are supported above the subfloor on the walls. Suspended timber floors can be cold, drafty and potentially damper than solid floors, which is why underfloor heating can be a perfect solution. Suspended floors do not conduct heat as efficiently as screed or concrete floors, so if there is the opportunity to consider replacing them with a solid floor the performance of the underfloor heating will be improved.

A lot of older properties incorporate timber-suspended floors.

Underfloor heating with timber floors heats up and cools down rapidly, much like a conventional radiator system. Systems rely on the conductivity of components fitted within the floor to transfer heat from the pipes to the surface.

It is crucial to have an underfloor design and decide where best to situate controls for ease of use. Planning and design will determine where the pipes will run through the joists. Your plan should include every area to be heated. If the installation is to be installed zone by zone, this will ensure that the system will integrate to work efficiently.

There are several ways to install your underfloor heating with timber floors, depending on time constraints and budget.

Between Joists with Screed

The first method uses a screed. We have found this to be the least popular of our installations. The air void between the insulation and floorboards gets infilled using a biscuit screed mix at a depth of 25mm. This method turns the structure into a screed floor, which acts like a storage heater. A structural engineer must undertake the design to ensure the joists can cope with the loadings to be applied.

Above Joists with Screed

The insulation is fixed tight between the joists. Timber boards are fixed directly to the top. Battens are fixed to the boards leaving gaps on either end for pipes to pass through. Screed gets used to encapsulate UFH pipes. This method turns the structure into a screed floor, which acts like a storage heater. A structural engineer must undertake the design to ensure the joists can cope with the loadings to be applied.

As an alternative to the suspended screed floors are aluminium spreader plates, pre-bent for secure pipework positioning. These enable homogenous heat transmission. These are generally laid over the joists and screwed or stapled in place. The panels should be staggered to avoid corner joints between four adjacent panels.

Insulation can be placed in the space below the plates to minimise any downward heat loss and dissipate the heat evenly across the floor, avoiding cold spots.

Spreader plates have several advantages:

- Easy to install for the DIY installer as they set the pipe spacing

- Lightweight and manoeuvrable

- Clean and mess-free installation

- Quick to fit

- Spread the heat evenly when used with insulation alone

- Suitable for either new builds or retrofitting

An even floor thickness is required. In areas with no underfloor heating pipes, such as under baths, kitchen units or fitted cupboards, the level needs maintaining by replacing the screed or plates with plywood or chipboard.

Get Exclusive Updates

Sign up for our newsletter to receive exclusive news, offers and promotions:

We take your privacy seriously, please see our privacy policy for more information.

Our Happy Customers

Thank you to our customers for reaching out and providing us with valuable feedback.